Products

Adjustable Vehicle Tyre Changer

Feature

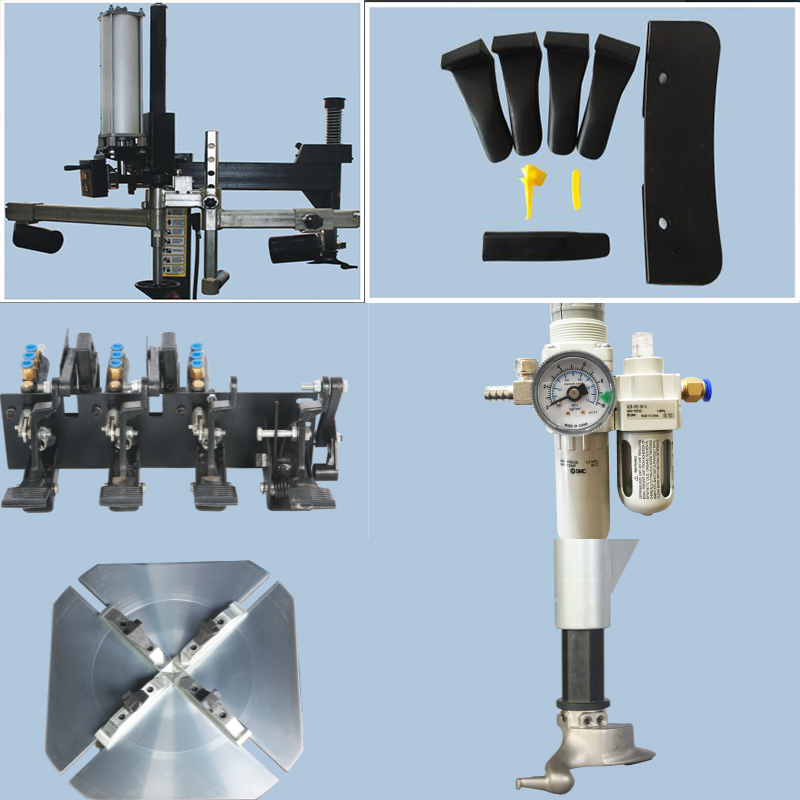

1.Foot valve fine structure can be removed as a whole, operation stably and reliably, and easy maintenance ;

2.Mounting head and grip jaw are made of Alloy steel;

3.Simple helping arm, save the operator operating time;

4.Adjustable Grip Jaw(option),±2”can be adjusted on the basic

clamping size.

Specification

| Motor power | 1.1kw/0.75kw/0.55kw |

| Power supply | 110V/220V/240V/380V/415V |

| Max. wheel diameter | 44"/1120mm |

| Max. wheel width | 14"/360mm |

| Outside clamping | 10"-21" |

| Inside clamping | 12"-24" |

| Air supply | 8-10bar |

| Rotation speed | 6rpm |

| Bead breaker force | 2500Kg |

| Noise level | <70dB |

| Weight | 298Kg |

| Package size | 1100*950*950mm |

| 24 units can be loaded into one 20”container | |

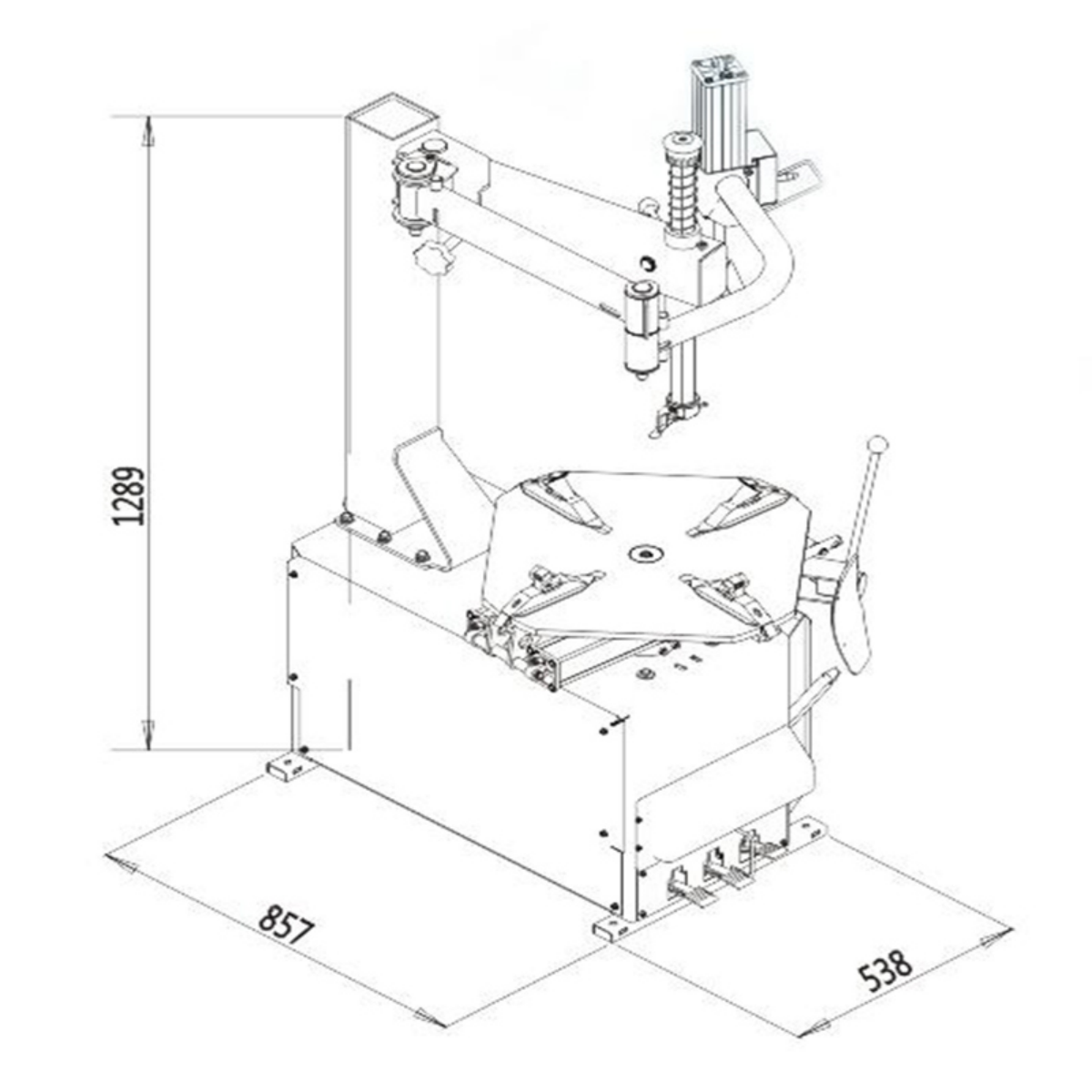

Drawing

Installation of tires

1.Apply grease to the inside edge of the tire first.

2.Fix the steel ring on the turntable in the same way as removing the tire, put the tire on the upper edge of the steel ring, and determine the position of the air hole.

3.Move the dismounting arm to press the edge of the tire, step on the pedal, and gradually press the tire into the steel rim.

4.Press the upper tire into the steel rim in the same way to complete the tire installation.

Daily maintenance

1.Clean the dust on the turntable in time after using machine.

2.Check whether the grinding block on the mounting head is worn out before using the machine, and replace it in time if it is worn out.

3.Check the liquid level of lubricating oil in the oil-water separator every week, if the liquid level is lower than the minimum mark, it must be filled in time. It is necessary to adjust the amount of lubricating oil to avoid too much or too little.

4.Check whether there is water in the water filter every month. If there is water, drain it in time, and do not let the water exceed the maximum line.