Products

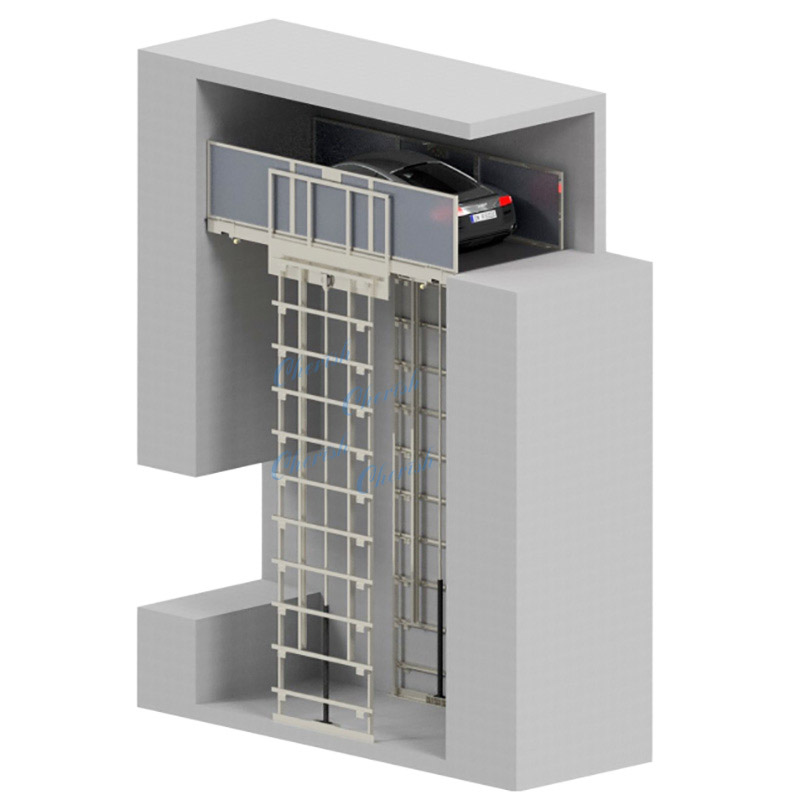

Car Elevator Double Rail Lift

Rail lift

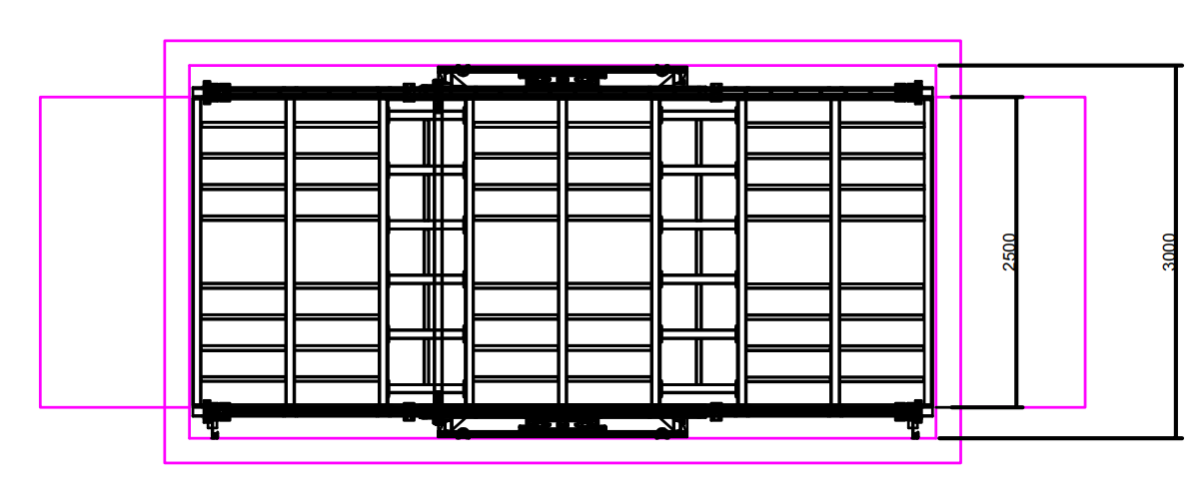

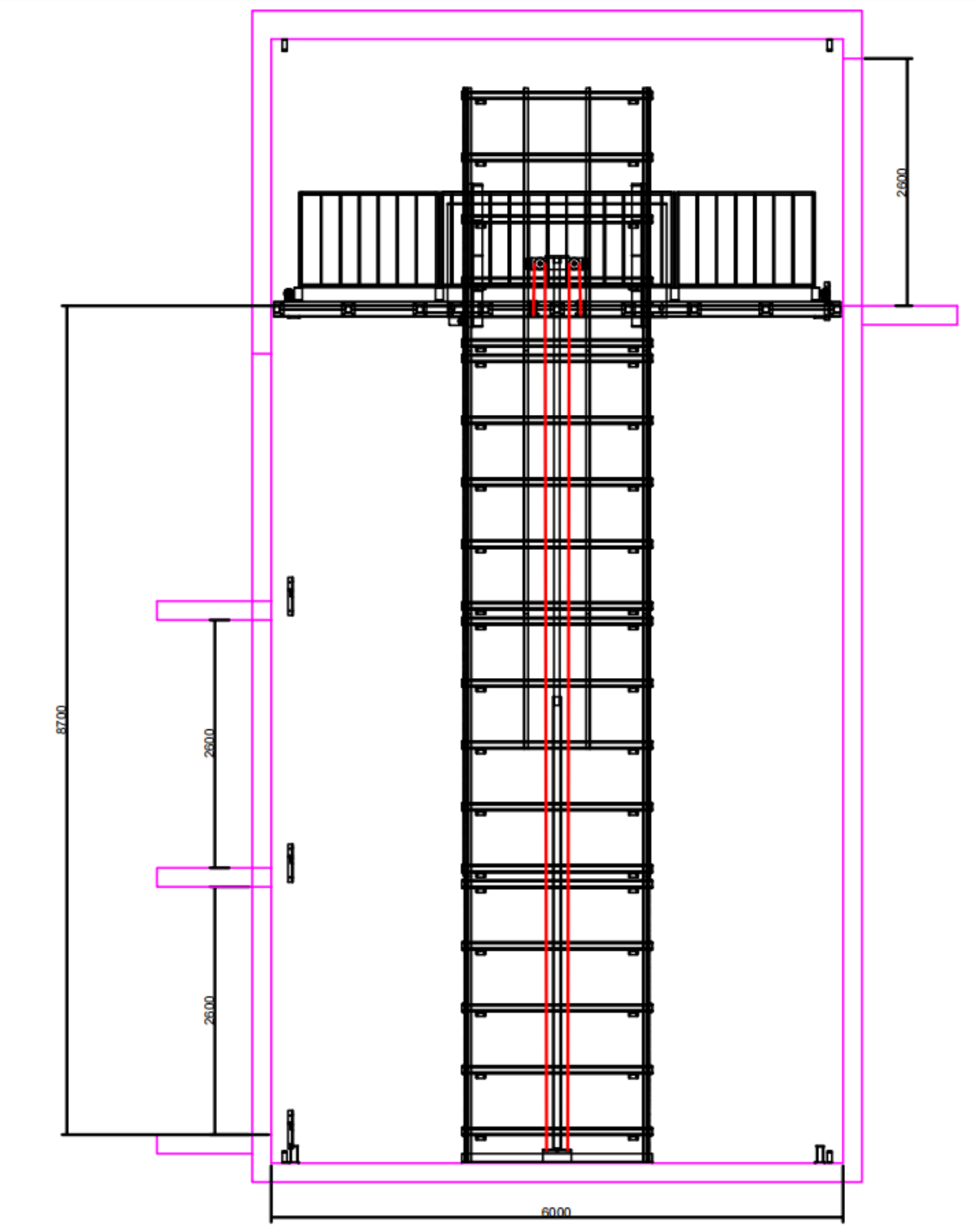

■ Stroke = up to 12000 mm

■ Platform length = up to 6000 mm

■ Platform width = up to 3000 mm

■ maximum load = up to 3000 kg

■ Speed = 7 to 10 cm/sec

Specification

|

Pit length |

6000mm |

|

Pit width |

3000mm |

|

Platform width |

2500mm |

|

Loading capacity |

3000kg |

Note

1.At least the greatest possible car height + 5 cm.

2.Ventilation in the lift shaft is to be provided on site. For the exact dimensions, please contact us.

3.Equipotential bonding from the foundation earth connection to the system (on site).

4.Drainage pit : 50 x 50 x 50 cm, installation of a sump pump (see manufacturer's instructions). Please contact us before determining the location of the pump sump.

5.No fillets/haunches are possible at the transition from the pit floor to the walls. If fillets/haunches are required, the systems must be narrower or the pits wider.

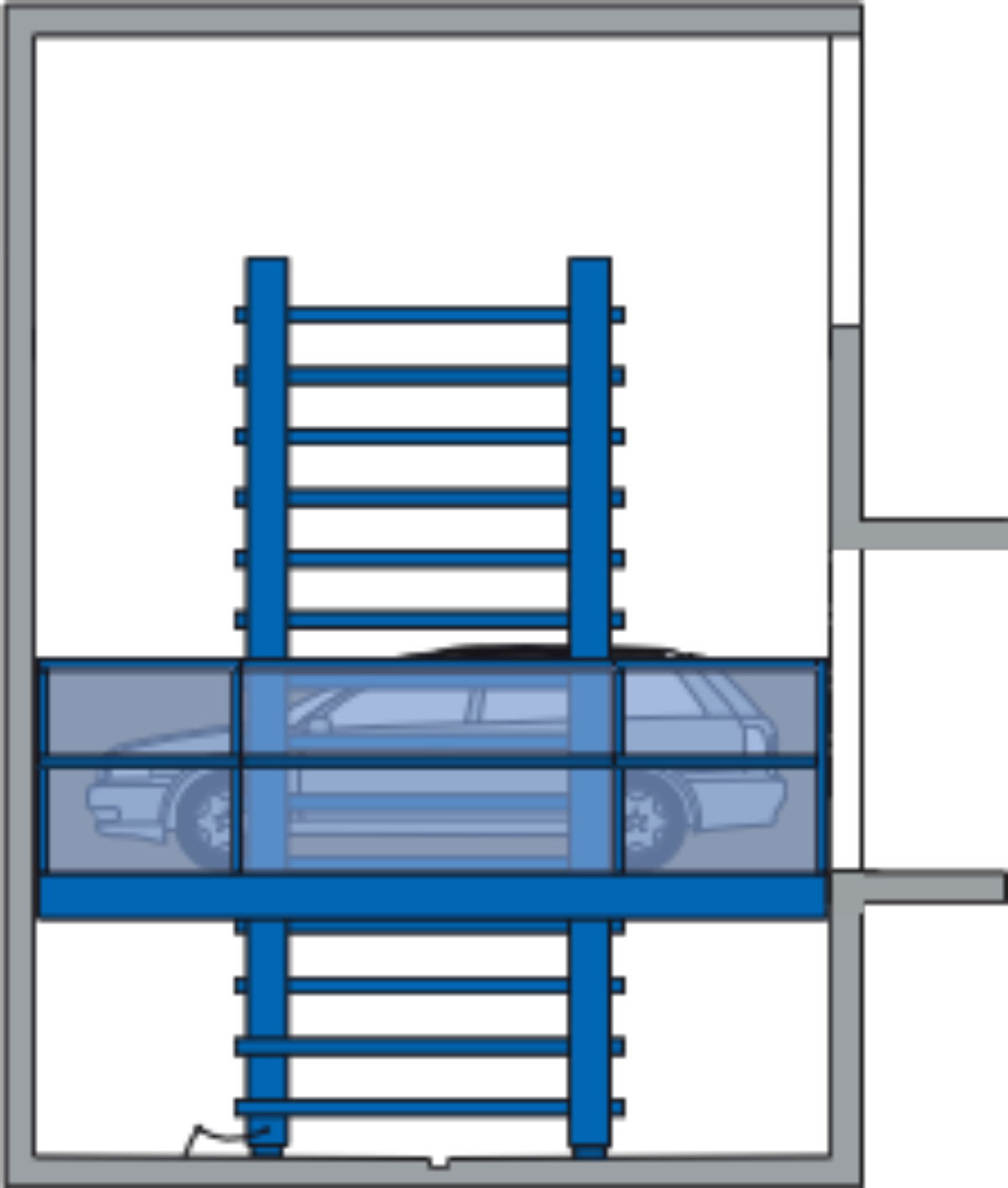

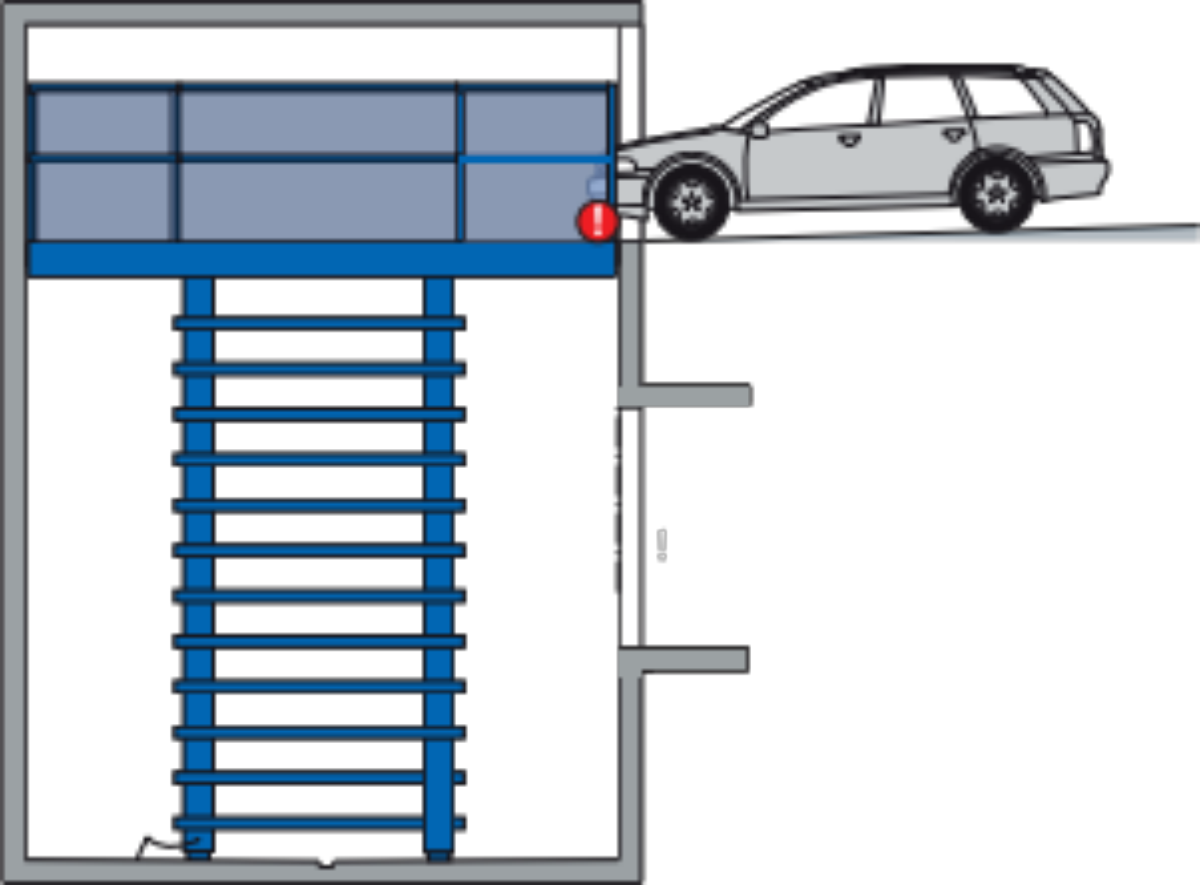

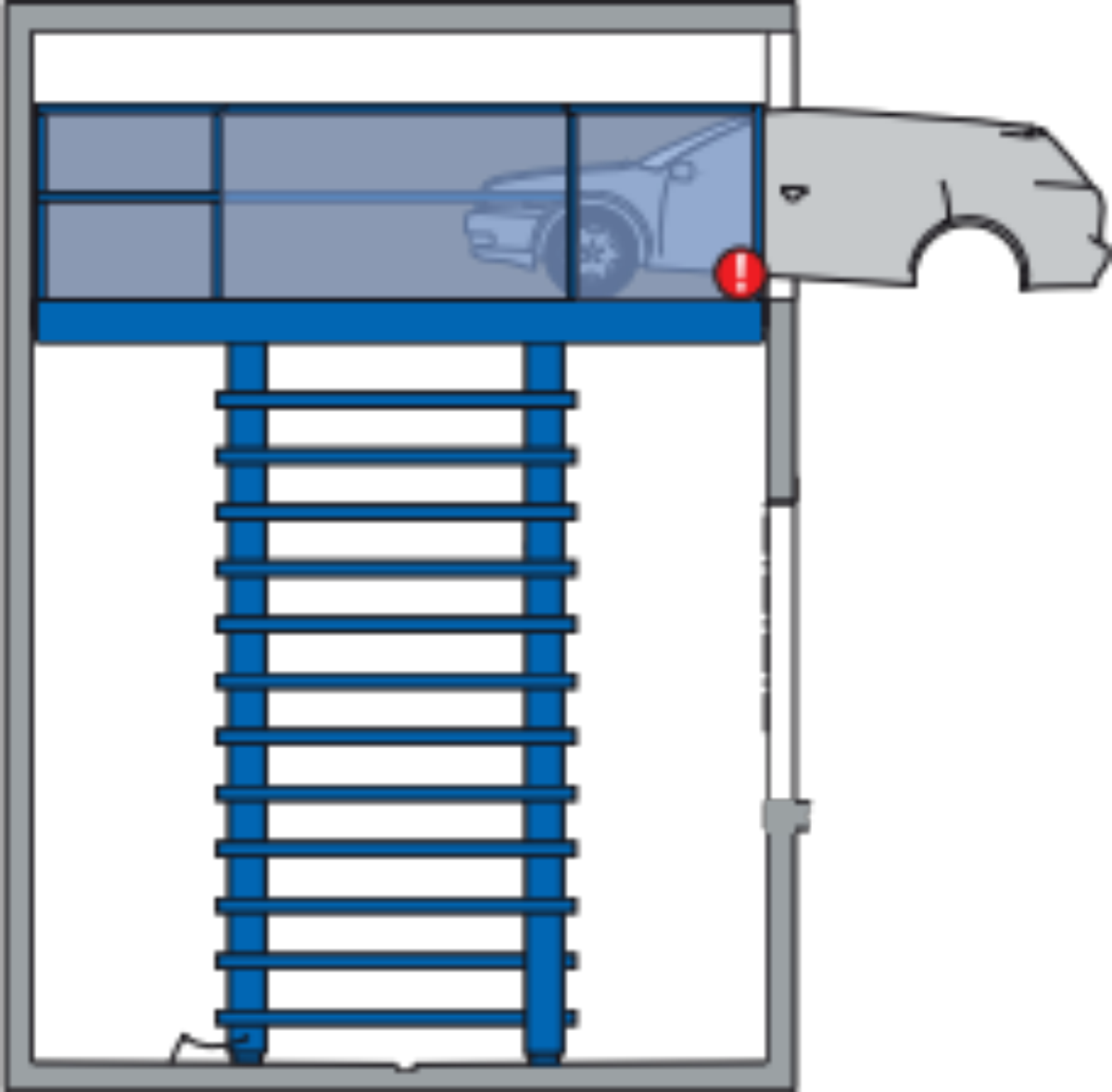

Elevator position

Elevator with garage door

Driveway

The maximum access inclines specified in the symbol sketch must not be exceeded.

If the access road is incorrectly executed, there will be considerable difficulties when entering the facility, for which Cherish is not responsible.

Detail construction - hydraulic & electric unit

The space in which the hydraulic power unit and electrical panel will be housed should be carefully selected and easily accessible from the outside. It is recommended to close this room with a door.

■ Shaft pit and machine room are to be provided with an oil-resistant coating.

■ The technical room must have adequate ventilation to prevent the electric motor and hydraulic oil from overheating. (<50°C).

■ Please pay attention to the PVC pipe for the correct stowage of the cables.

■ Two empty pipes with a minimum diameter of 100 mm must be provided for the lines from the control cabinet to the technical pit. Avoid bends of >90°.

■ When positioning the control cabinet and the hydraulic unit, take the specified dimensions into account and ensure there is sufficient space in front of the control cabinet to ensure easy maintenance.

Load plan

The systems are anchored in the ground. The drill hole depth in the base plate is approx. 15 cm, in the walls approx. 12 cm.

Floor slab and walls are to be made of concrete (concrete quality min. C20/25)!

The dimensions of the support points are rounded. If the exact location is required, please contact us.

Instruction

Usage

The system is suitable for indoor installation and for lifting cars. The car lift is suitable for both residential and office buildings. Please contact Cherish for advice.

Aggregate

We recommend separating the garage superstructure from the residential building. The hydraulic unit and the electrical components should be housed in a cabinet

CE-certificate

The systems offered correspond to the EC Machinery Directive 2006/42/EC.

building application documents

The Cherish systems are subject to approval according to the EC Machinery Directive 2006/42/EC. Please refer to local rules and regulations.

Environmental conditions

■ Temperature range -10 °C to +40 °C

■ Relative humidity 50% at a maximum outside temperature of +40° C.

If lifting or lowering times are mentioned, these relate to an ambient temperature of +10° C and the system being arranged directly next to the hydraulic unit. These times increase at lower temperatures or longer hydraulic lines.

Protection

To avoid corrosion damage, please observe the separate cleaning and care instructions (see "Corrosion protection" sheet) and ensure that your garage is well ventilated.