Products

Semi Automatic Car Tyre Changer

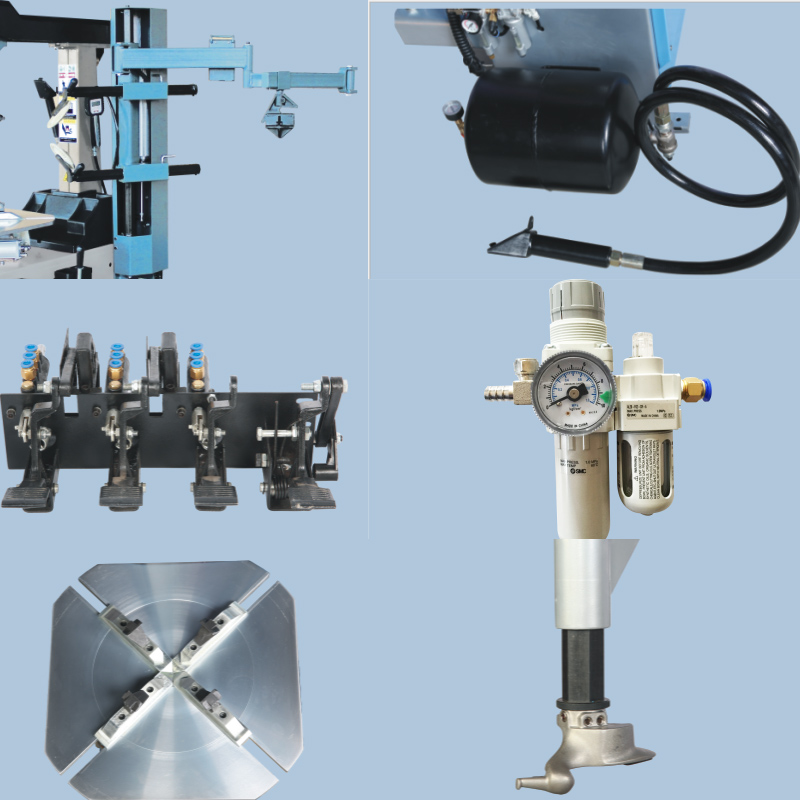

Feature

1.Foot valve fine structure can be removed as a whole, operation stably and reliably, and easy maintenance ;

2.Mounting head and grip jaw are made of Alloy steel;

3.S41 hexagonal oriented tube extended to 270mm, effectively prevent the deformation of the hexagonal shaft;

4.Pressure tyre lever, assistance for handing run flat, low-profile and stiff tyres;

5.Reserved helper fixing hole, which is easy to fix the helper at customer’s requirement.

Specification

| Motor power | 1.1kw/0.75kw/0.55kw |

| Power supply | 110V/220V/240V/380V/415V |

| Max. wheel diameter | 44"/1120mm |

| Max. wheel width | 14"/360mm |

| Outside clamping | 10"-21" |

| Inside clamping | 12"-24" |

| Air supply | 8-10bar |

| Rotation speed | 6rpm |

| Bead breaker force | 2500Kg |

| Noise level | <70dB |

| Weight | 295Kg |

| Package size | 1100*950*950mm |

| 24 units can be loaded into one 20”container | |

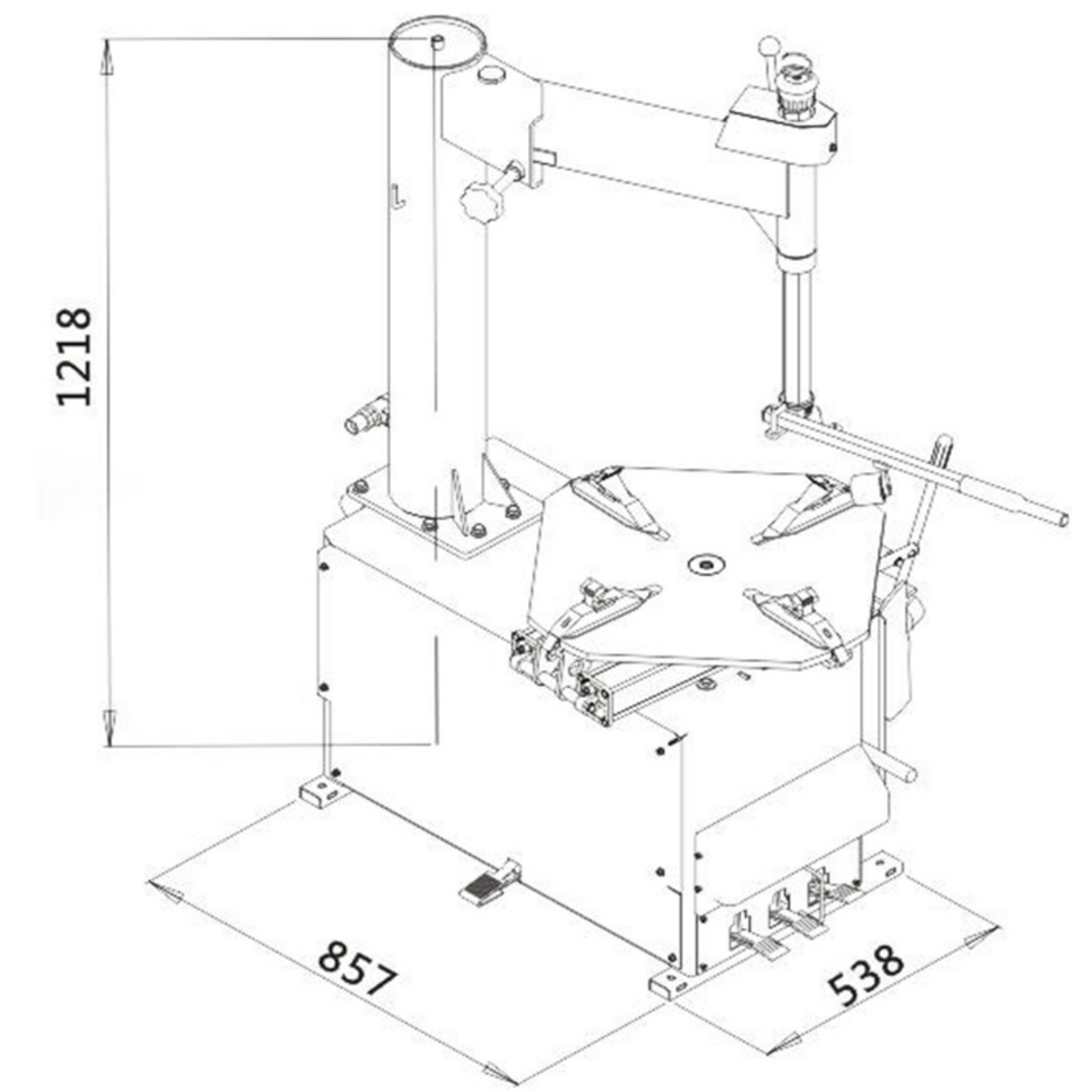

Drawing

Grilling steps

1. Remove the air from the tire.

2. Remove all lead weights from the rim.

3. Put the tire in the designated position, rotate the tire repeatedly and press down the tire shovel, step on the tire shovel pedal to completely separate the tire from the steel ring.

4. Place the rim on the turntable and depress the tire clamp pedal to lock the rim.

5. Apply grease to the inner ring of the tire.

6. Pull down the disassembly arm so that the inner roller of the chuck sticks to the edge of the steel ring, and lock the extension lock arm of the head with the telescopic arm lock of the head.

7. Use a crowbar to lift the tire to the pick-up head, step on the turntable pedal to rotate the chuck, and pick one side of the tire out.

8. Pull out the other tire in the same way.