Products

Semi Automatic Vehicle Wheel Balancer

Feature

1.The caliper can measure the distance

2.With self-calibration balancing function

3.Tyre balance optimizatio

4.Balancing the motorcycle tyre with adapter optional

5.Equipped with conversion function from inch to millimeter and gram to ounce

6.The enhanced balance shaft, good stability, suitable for all kinds of flat wheel measurement.

Specification

| Motor power | 0.25kw/0.32kw |

| Power supply | 110V/220V/240V, 1ph, 50/60hz |

| Rim diameter | 254-615mm/10”-24” |

| Rim width | 40-510mm”/1.5”-20” |

| Max. wheel weight | 65kg |

| Max. wheel diameter | 37”/940mm |

| Balancing precision | ±1g |

| Balancing speed | 200rpm |

| Noise level | <70dB |

| Weight | 112kg |

| Package size | 1000*900*1100mm |

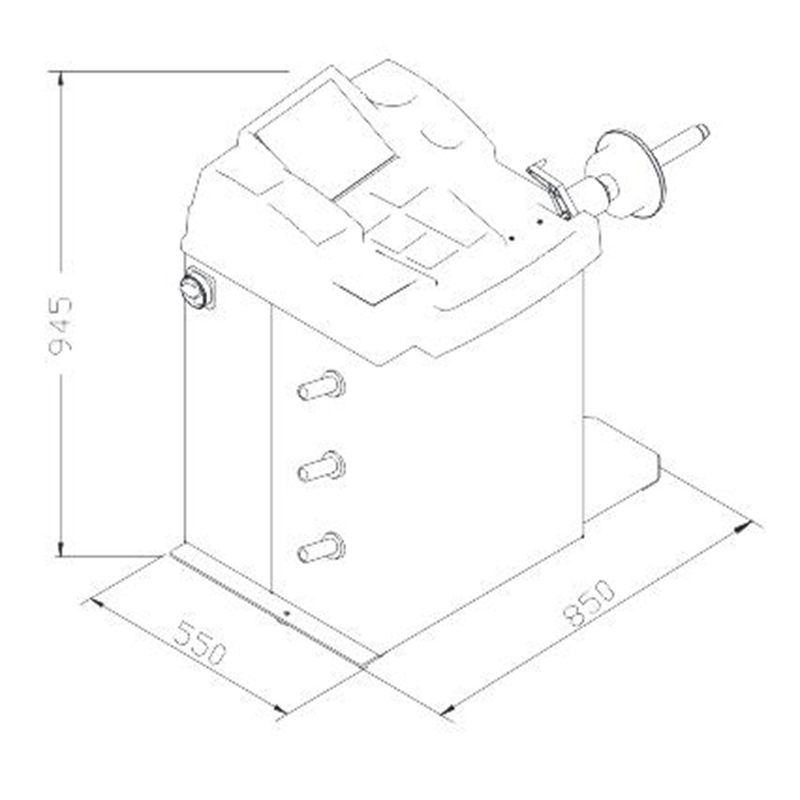

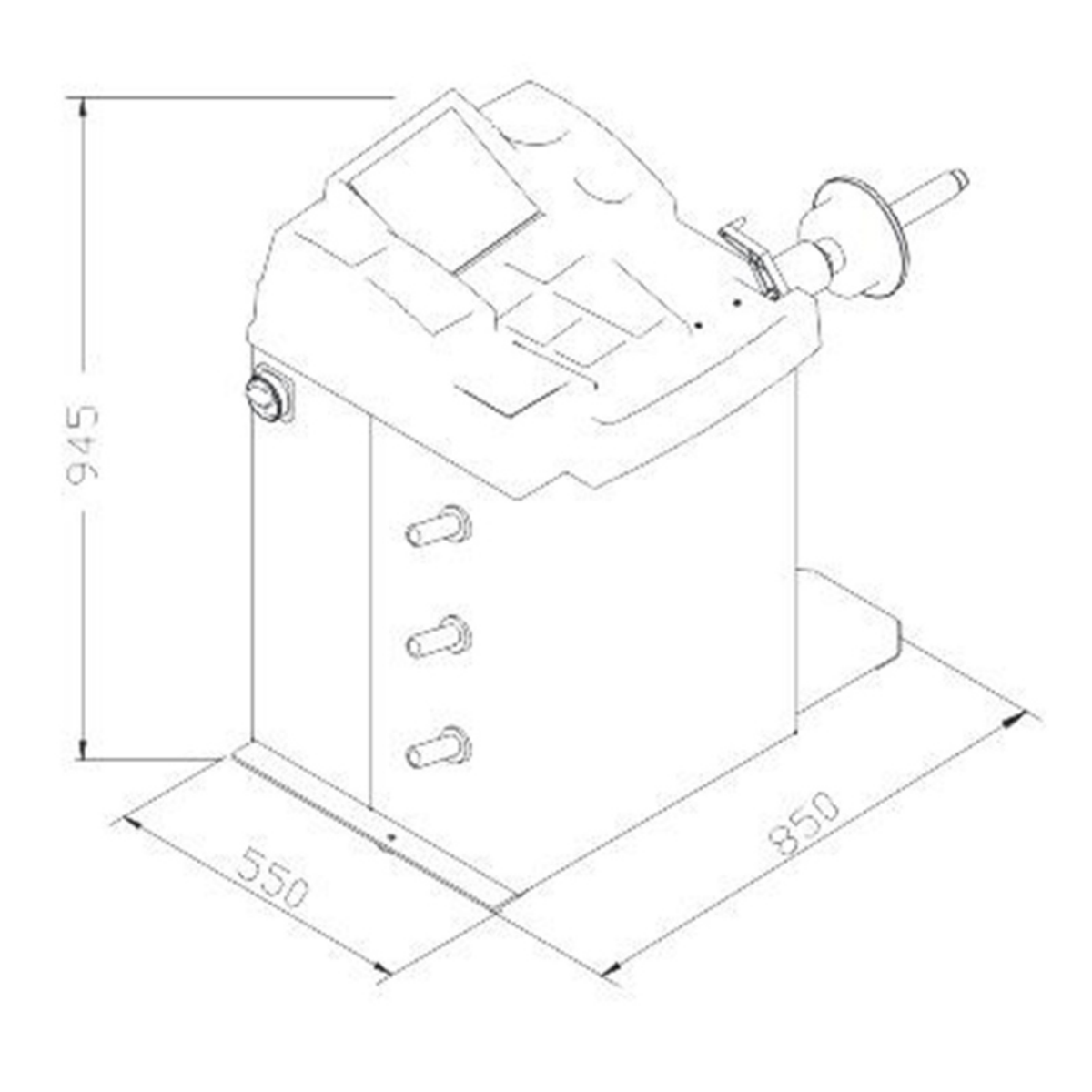

Drawing

Principle of tire balancer

When the wheels of the car rotate at high speed, a dynamic unbalanced state will be formed, causing the wheels and steering wheel to vibrate during driving. In order to avoid or eliminate this phenomenon, it is necessary to make the wheel correct the balance of each edge part by increasing the counterweight under dynamic conditions.

First, start the motor to drive the tire to rotate, and due to the unbalanced parameters, the centrifugal force exerted by the tire on the piezoelectric sensor in all directions is converted into an electrical signal. Through continuous measurement of the signal, the computer system analyzes the signal, calculates the size of the unbalanced quantity and the minimum position of the parameter, and displays it on the screen system. In order to meet the requirement of minimum unbalance, the sensor and A/D converter in the system must use high-sensitivity and high-precision products. So the computing speed and testing speed of the system need to be high.