Products

Truck Automatic Tyre Changer and Helper

Feature

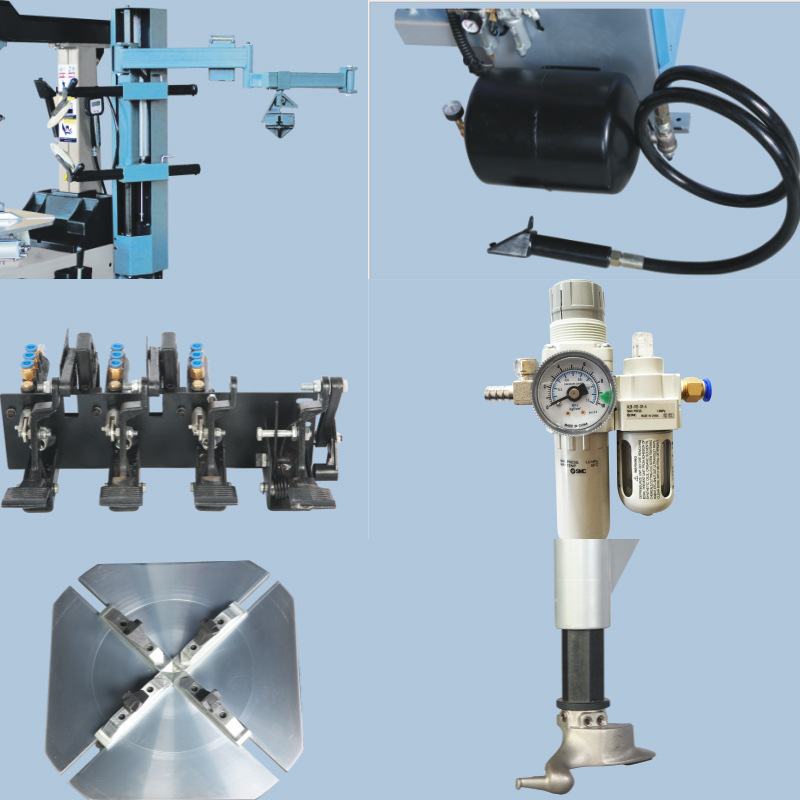

1.Tilting column and pneumatic locking mount & demount arm ;

2.Six-axis oriented tube extends to 270mm can prevent effectively deformation of six-axis;

3.Foot valve fine structure can be demount as a whole, operation stably and reliably, and easy maintenance ;

4.Mounting head and grip jaw are made of Alloy steel;

5.Adjustable Grip Jaw(option),±2”can be adjusted on the basic clamping size;

6.Equipped with the external air tank jet-blast device, controlled by a unique foot valve and hand-held pneumatic device;

7.With power assist arm for handing wide, low-profile and stiff tyres.

Specification

| Motor power | 1.1kw/0.75kw/0.55kw |

| Power supply | 110V/220V/240V/380V/415V |

| Max. wheel diameter | 44"/1120mm |

| Max. wheel width | 14"/360mm |

| Outside clamping | 10"-21" |

| Inside clamping | 12"-24" |

| Air supply | 8-10bar |

| Rotation speed | 6rpm |

| Bead breaker force | 2500Kg |

| Noise level | <70dB |

| Weight | 384Kg |

| Package size | 1100*950*950mm,1330*1080*300mm |

| 24 units can be loaded into one 20”container | |

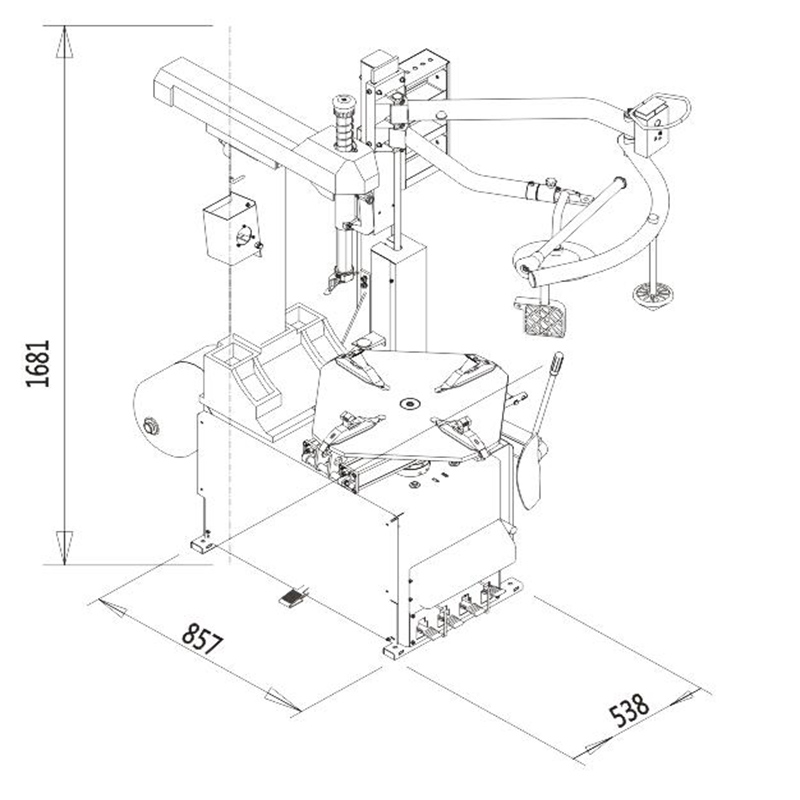

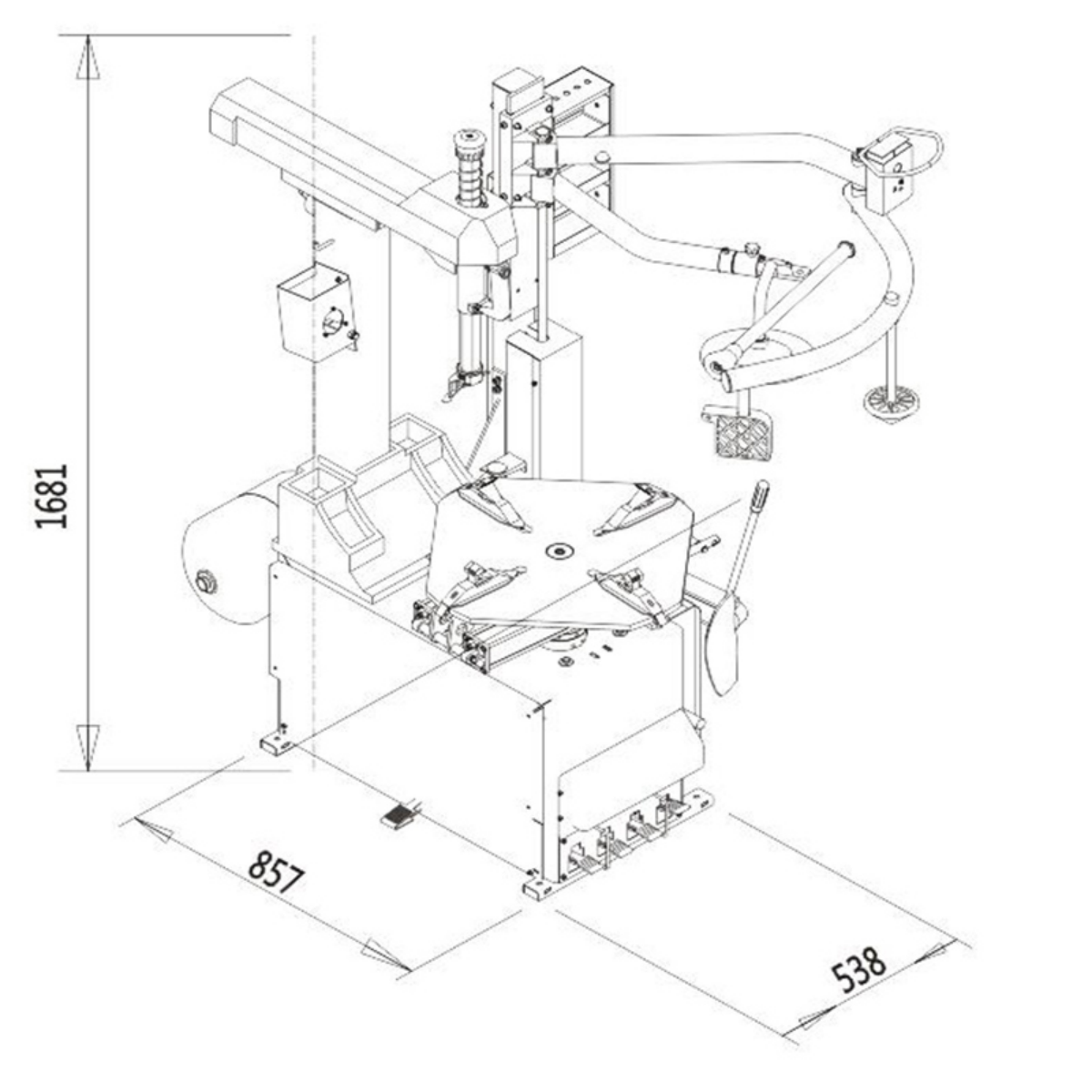

Drawing

Maintenance of tyre changing machine

1. The power and air source must be disconnected before maintenance.

2. The machine needs to be carefully wiped, and the sliding and transfer parts should be lubricated frequently after the daily operation.

3. Frequently check the gas-water separator and lubricator, discharge it in time when there is too much water, and replenish it in time when the oil is insufficient.

4. Ensure that there is enough lubricating oil in the reduction box. You can see the oil level from the oil window. Open the plastic cover in the center of the workbench, unscrew the bolts, and then add oil from the bolt holes.