Products

Truck Car Vehicle Wheel Balancer

Feature

1.Both truck and car switchover;

2.Pneumatic braking;

3.Pneumatic lift for large wheel loading;

4.Self calibration;

5.Unbalance optimization function;

6.Measurements in inches or millimeters, readout in gram or oz;

Specification

| Motor power | 0.55kw/0.8kw |

| Power supply | 220V/380V/415V, 50/60hz, 3ph |

| Rim diameter | 305-615mm/12””-24” |

| Rim width | 76-510mm”/3”-20” |

| Max. wheel weight | 200kg |

| Max. wheel diameter | 50”/1270mm |

| Balancing precision | Car ±1g Truck ±25g |

| Balancing speed | 210rpm |

| Noise level | <70dB |

| Weight | 200kg |

| Package size | 1250*1000*1250mm |

| 9 units can be loaded into one 20”container | |

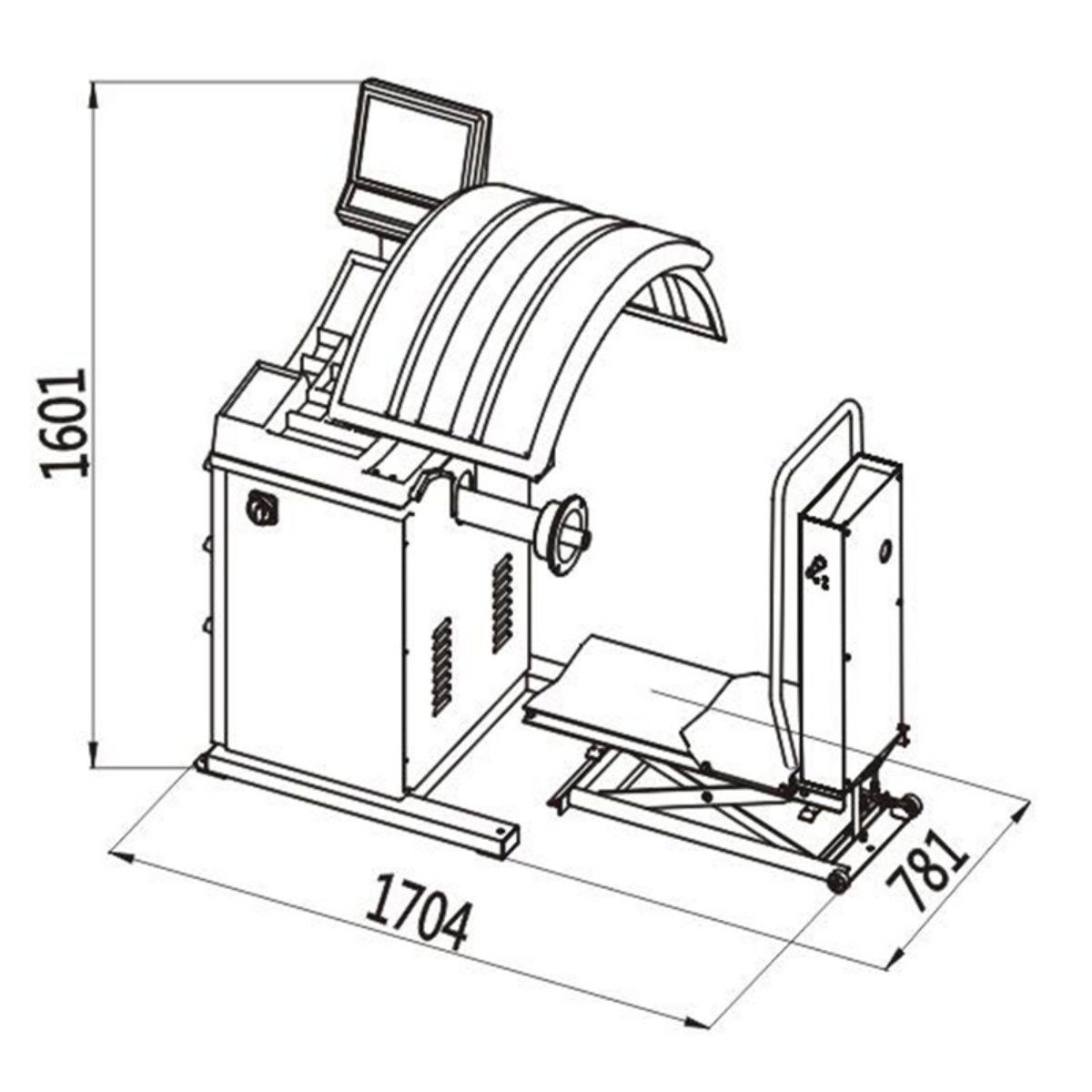

Drawing

FAQ

What preparations should be made before the wheel is dynamically balanced?

1. Clean and check the tires. There should be no stones in the tire tread. If there are any, remove them with a screwdriver or other tools. There should be no sediment accumulation on the hub, if there is any, wipe it clean with a cloth.

2. Check the tire pressure. The tire pressure should be at the standard value. The standard value of the tire pressure can be found at the door frame of the driver's seat, usually 2.5bar.

3. The original dynamic balance block on the tire should be completely removed.

How many times do you use wheel balancer? If it has not been corrected more than three times, what is the reason?

Generally, you can correct the wheel at one or twice. In rare cases, three times the tire can be corrected. If the tire is still not repaired after running the tire for more than three times, it may be that the tire and wheel hub are not assembled properly, or there are impurities such as tire sealant fluid and falling objects in the tire. Then check these parts and try again.